-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

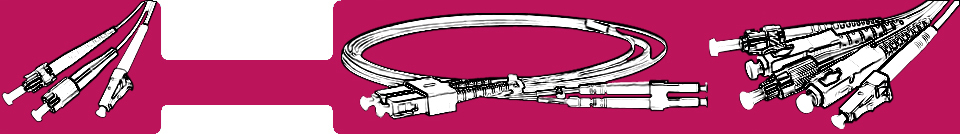

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

Fabric and/or composite material wipes provide combined mechanical action and absorbency to remove contamination. Wipes should be used with a resilient pad in order avoid potential scratching of the connector end-face. This method is appropriate for cleaning connectors with exposed ferrules or termini but cannot be used to clean connector end-faces within alignment sleeves.

The wipe should be constructed of material that is lint free and non-debris producing during the cleaning process. Please note that dry wipes have been shown to leave a static charge on the end-face of the connector which can thereafter attract particulate contamination. Therefore it is recommended that a static dissipative solvent be used with a dry wipe to eliminate this condition.

- Technique for Cleaning with Wipes or Cleaning Cassette

.png)

Lint free wipes cleaning fiber connector

As mentioned above it is recommended to use a lint-free, non-debris generating wipe with a static dissipative solvent. The user should dampen a portion of the wipe with the solvent, place the connector end-face into the damp area of the wipe and draw the connector into the dry area of the wipe. A physical wipe of 2 – 5 cm should be sufficient. This may be repeated in a different area of the wipe if desired, however 1 or 2 strokes should be sufficient for most common contaminants.

.png)

Fiber connector cassette cleaning

Upon inspection, if the connector is not clean after the first cleaning, the process can be repeated perhaps with slightly more pressure on the connector to increase the mechanical action and perhaps making several stokes from the damp to dry sections of the cleaning material.

If the connector is still not clean and contamination has not moved it should be considered non-removable contamination and depending on the location and size of the contamination the user should pass or reject use of the connector.

- Swabs or Port Cleaning Device

Use of purpose built swabs or mechanical port cleaning devices provides mechanical action and absorbency to remove contamination. However since the area within a port is very confined and limits mechanical action, it is recommended that a wet/dry cleaning process be utilized for cleaning connector end-faces within alignment sleeves.

A static dissipative solvent will add chemical action to the cleaning process as well eliminate any residual static charge that may be on connector. The cleaning end of the swab or cleaning material used in the port cleaning device should be lint free, non-debris generating material.

Select a swab or port cleaning device that is manufactured for the size connector you are cleaning. Do not touch or contaminate the cleaning end of the swab or the port cleaning device. It is recommended that the user dampen the swab or port cleaning device with a static dissipative solvent.

The swab or port cleaning device should be damp and not wet. (The process is analogous to wiping a smooth surface with a sponge. A damp sponge will pick up contaminates, whereas a wet sponge will only spread them around.) If a very fast drying solvent is used then a follow-up cleaning with a dry swab or an addition activation of the port cleaning device may not be necessary.

3. Swab Cleaning Detail

.png)

Swab fiber cleaning

Place the dampened cleaning end of the swab into the port and rotate the swab while applying some pressure to the connector end-face. Usually pushing so that the compression spring in the connector is slightly activated is ideal for 2.5mm connectors. Rotating the swab 6 – 12 times is sufficient. The swab should only be used once and then disposed.

If the user is cleaning angled polished connectors – APC (typically color coded with a green connector housing or bulkhead adaptor), then using a ¼ turn back and forth rotation may help the swab end-face conform to the 8 degree angle and thereby clean the entire surface of the connector end-face.

If a very fast drying solvent was used, you are now ready to inspect. If not, repeat the above process with a dry swab.

4. Port Device Cleaning Detail

MTP in bulkhead cleaner

Insert the solvent dampened device into the alignment sleeve and active the cleaner to perform the mechanical clean either by pushing the device or by pressing on a button on the device. An additional activation of the device assures that any excess solvent has been removed. Upon inspection, if the connector is not clean after the first cleaning, the process can be repeated.

If the connector is still not clean and contamination has not moved it should be considered non-removable contamination and depending on the location and size of the contamination the user should pass or reject use of the connector.

5. About Solvents

Solvents used to clean fiber optics should be static-dissipative and residue-free. Many solvents are flammable and/or packaged so that transportation of the solvent is considered a hazardous material increasing cost of shipment and storage of the solvent.

However, there are solvents available that are non-flammable and non-hazardous and packaged so that shipping requires no additional fees or paperwork. Historically, 99% pure isopropyl alcohol (IPA) has been used as a solvent. However, IPA is easily contaminated.

The solvent is hygroscopic and therefore absorbs moisture from the atmosphere including any contaminates present contaminating the solvent and potentially leaving a haze on the connector end-face which can be a problem with higher power laser networks.

In addition, IPA is flammable and is considered a hazardous material. Typically IPA must be repackaged for use and is therefore very subject to contamination. Also, it is important to select a solvent that is compatible with the cleaning wipe, swab, or device. You do not want a solvent will dissolve a binder or glue used in a wipe or swab and generate additional contamination.

Sopto supply fiber optic patch cords with good quality fiber optic connectors, like LC, ST, FC, SC and so on. For the newest quotes, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com. For more info, please browse our website.